Latest News

Honoring Our Veterans - November 2022

Honoring Our Veterans

2019 AD Marketplace Supplier of the Year

AAPEX 2019

Rib Ace® Fit belt

2019 AD Marketplace Supplier of the Year

2018 IDC-USA Marketplace Award Winner

Toothed Rib Belt

Heat Carry™ Conveyor Belts

XL, L, H

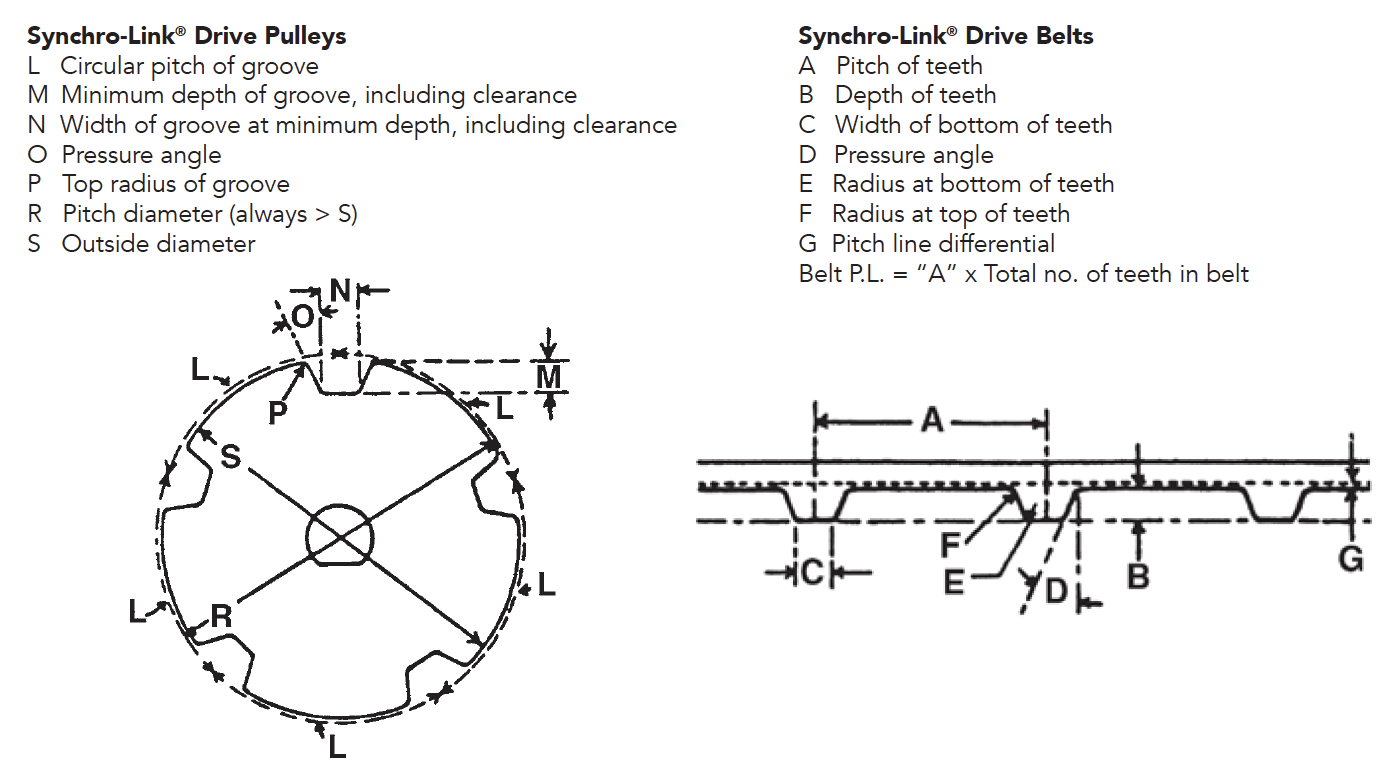

Synchro-Link® Trapezoidal MPB construction

trapezoidal profiles

The type of pulley used on a Synchro-Link® drive depends on a number of factors, including but not limited to, space available, ratios, center distances, horsepower being transmitted, speeds, and user preference of mounting systems (i.e. QD®, TL® or Minimum Plain Bore).

An Explanation of Synchro-Link® Drive Pitches

With Synchro-Link® Drives, as with gear or chain drives, circular pitch (usually referred to as pitch) is a fundamental consideration. On the belt, the pitch is the distance between tooth centers and is measured on the pitch line of the belt. On the pulley, the pitch is the distance between groove centers and is measured on the pulley’s pitch curve.

The pitch line of a Synchro-Link® Drive Belt is located within the tension member. The pitch circle of a Synchro-Link® Drive Belt pulley coincides with the pitch line of the belt mating with it.

Any Synchro-Link® Drive Belt must be run with pulleys of the same pitch. A belt of one pitch cannot be used successfully with pulleys of a different pitch.

Rebore, Keyway, and Setscrew Alterations

A minimum quantity of 100 identical sizes of MPB Synchro-Link® pulleys is required for any alteration, i.e.: reboring, keywaying, or additional setscrews. Consult Bando for price and availability.